07.11.2023

Applying the Hierarchy of Controls to Working in Heat

Every year, thousands of workers become ill, and in some cases suffer fatal consequences while working in hot or humid conditions. This is due to heat illness or exhaustion, but it is preventable. At Faith Technologies, we work hard to ensure our team members are aware of the hazards of working in hot environments. We’ve made a commitment to maintain an “Uncompromised Focus on Keeping People Safe” and do so by following the hierarchy of controls as closely as possible in the working conditions we are tasked with.

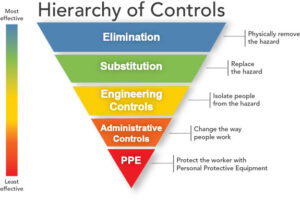

The National Institute for Occupational Safety & Health (NIOSH) describes the hierarchy of controls as a method of identifying and ranking safeguards to protect workers from hazards. As seen in the image, elimination of the hazard is always the most effective, but it is not always possible. For working in heat, engineering controls, administrative controls and personal protective equipment are the most commonly used controls across industries.

Engineering controls are best explained as using mechanical advantages to find the safest result. Some of these include providing additional air conditioning to the work environment, adding cooling fans, local exhaust ventilation, designated cooled break areas and possibly installation of mechanical equipment to eliminate more strenuous tasks. These controls may be be more costly on the front end of the business but will provide return on investment through employee morale, less absenteeism, better overall production and safer work conditions.

Administrative controls focus more on the duration, frequency and intensity while working in these environments. We focus on these controls when the engineering controls are not as feasible. Some of these may include training team members on proper water, rest and shade in the work environment, and the signs and symptoms of heat illness and when to respond. Modifying work schedules for employees newer to the work environment and acclimatizing newer employees with shorter shifts can also help. Requiring mandatory breaks in a cooler environment, rotating employees through different job functions and ensuring employees are properly hydrating with water or electrolytes before, during and after work can be effective. These administrative controls can be more cost effective and require less time to implement. They are not meant to replace engineering controls but rather support where the engineering controls might not be as effective or available.

Last on the hierarchy map is personal protective equipment (PPE). For some organizations, this is the only control implemented with the other controls forgotten. Although having the correct PPE is extremely important, don’t let this control fool you into being the only thing needed. PPE can be an effective last line of defense and must be used correctly and consistently. In heat environments, certain PPE like cooling neck wraps, hard hat sunshades and vented and cooling vest are great solutions in helping protect workers and may enable safe work for longer periods, but they do not replace the previously mentioned engineering or administrative controls to better protect your team.

Finding the right solutions to protect your team in heat environments depends on the scenario and activities they are tasked with. It is also important to consider other hazards that may arise in addition to heat, and then proceed in determining which controls are right for your team.

If you enjoyed this blog article, please subscribe to stay up to date on the latest industry news from our experts at Faith Technologies.