10.20.2015

Lack of Productivity in the Construction Industry: What’s the Problem, What’s the Fix?

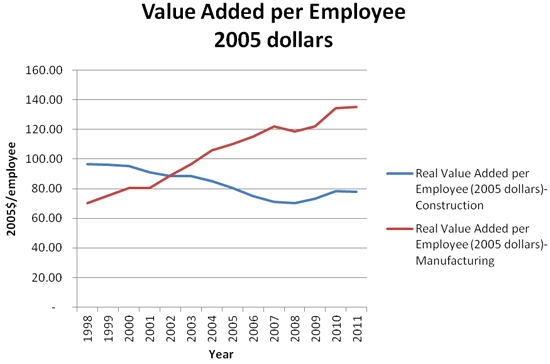

By every published measure, construction industry productivity seriously lags behind manufacturing industry productivity with little to no sign of improvement. The chart below shows the disparity and an actual decline in construction productivity:

Figure 1 – Value added in 2005 dollars per employee for the construction and manufacturing industries from 1998-2011 (Source: BEA Value Added and Employment Data by Industry)

Figure 1 – Value added in 2005 dollars per employee for the construction and manufacturing industries from 1998-2011 (Source: BEA Value Added and Employment Data by Industry)

Most who report on this topic identify two things:

- The lack of technological improvements in the construction industry.

- The difficult and varying environments that construction is faced with.

Having worked in both manufacturing and construction I have a different perspective regarding these issues. There is no question that Manufacturing has benefited from technological advances as well as a stable work environment. The major key to Manufacturing’s success is leadership has recognized the need for all of the various manufacturing functions, from material handling to production control, to operate as a cohesive team, performing the necessary non-value adding tasks and permitting the skilled worker to focus on value adding tasks (what the customer pays for). In the past, a machinist had to do everything from locating and moving his materials and tools, to determining feeds and speeds and programming the machine. Today, that machinist has become more of a machine operator, focusing on the value-adding work while the support functions perform the necessary non-value added work. These Lean manufacturing concepts help focus on reducing, eliminating or integrating non-value added work.

Let’s look at the contrast in construction. Each project has a varied mix of tradesmen from different companies which may include, masons, iron workers, plumbers and electricians. In most cases, the critical importance of ensuring this varied group works together as a cohesive team is not recognized or addressed. Thus their dependence on each other to achieve project success by completing work on schedule and under budget is missing a key ingredient – Teamwork. Construction leaderships failure to provide a clear understanding of the need to collaborate and work together is a major reason for the lack of productivity in construction. BIM (Building Information Modeling) is a technological advancement that holds promise for advancement, but it too requires collaboration and teamwork by all the trades.

The second key to improving productivity in the construction industry, is the need to provide the skilled tradesmen with support that completes the necessary non-value adding duties, allowing the skilled workers to focus the majority of their time on the value-added tasks that the customer pays them to do. Something manufacturing has long ago recognized and addressed. As opposed to the previous example of the machinist, the construction tradesmen continue to perform the necessary non-value added tasks that keep them from focusing on what the customer pays to be done.

Lean Construction principles hold promise for improving construction productivity, but just like BIM, success requires leadership, collaboration and a team approach.

At Faith Technologies, our productivity has improved dramatically by focusing our program on making certain our skilled electricians spend the majority of their time performing value-added work by providing support services that take care of the necessary non-value added duties. While it is critical that we at Faith Technologies continue to improve our productivity, overall construction productivity will not improve until construction industry leadership recognizes the importance of ensuring all the trades understand their dependence on each other and work together as a cohesive team. It’s not complicated.

That’s my take.

If you enjoyed this blog article, please subscribe to stay up to date on the latest industry news from our experts at Faith Technologies.