09.27.2018

Operational Risk Management Reduces Jobsite Safety Incidents

Many companies utilize risk assessment processes to identify and mitigate hazards on the jobsite. With all the risk assessment tools available, how do you choose the right one for your company? At Faith Technologies, we’ve implemented a standardized process called Operational Risk Management (ORM). This tool gives our employees a systematic process for identifying and controlling the risks involved in their daily tasks.

Many companies utilize risk assessment processes to identify and mitigate hazards on the jobsite. With all the risk assessment tools available, how do you choose the right one for your company? At Faith Technologies, we’ve implemented a standardized process called Operational Risk Management (ORM). This tool gives our employees a systematic process for identifying and controlling the risks involved in their daily tasks.

Operational Risk Management is the first task completed on every jobsite each day. Employees gather in the work area to plan their day by conducting a thorough ORM. Two formats are offered to employees to utilize as a guide: the first is a pre-printed dry erase board with the ORM model printed in the center, and the other is a paper book with multiple pages of the ORM model. Employees have the option of choosing the format that works best for their jobsite circumstance.

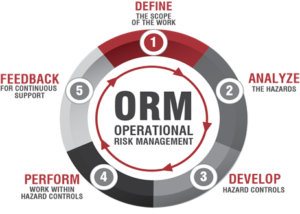

Operational Risk Management is a dynamic 5-step process which includes the following steps:

Operational Risk Management is a dynamic 5-step process which includes the following steps:

- Defining the scope of work: specific work tasks to be completed during an identified timeframe.

- Analyzing the hazards: each work task needs to be discussed and evaluated for potential risk.

- Developing hazard controls: a control method must be implemented for each identified risk. The Hierarchy of Controls are listed on the ORM board to provide guidance.

- Performing work within controls: crews develop methods to ensure control hazards are followed.

- Providing feedback for continuous support: this section allows the crew to analyze the effectiveness of the previous four steps.

Learn more about ORM and these 5 steps can improve productivity and efficiency.

Although each step in itself is important, it’s even more critical that all crew members are actively engaged in the ORM process. By discussing as a group, writing down the information, and reading through the content, it allows people with different learning styles to absorb and process the information three different ways. If tasks change throughout the day, the crew conducts the ORM process again to analyze the new tasks and hazards.

Since implementing the Operational Risk Management process, jobsite communication has improved, safety discussions have increased, and our incidents have been significantly reduced. Although Faith Technologies did not develop this process, we continue to tailor it to best fit our needs based on employee feedback.

Risk assessments are an effective injury prevention tool when they are integrated into the daily business activities. What methods do you use to increase employee involvement in risk analysis?

If you enjoyed this blog article, please subscribe to stay up to date on the latest industry news from our experts at Faith Technologies.